Philip

Thomson in Conversation with Peter Matzhold

Not often do I hear

one pipe maker bragging about another pipe maker’s briar. At first I did a

double take.

I had travelled to

northern Germany to meet a Danish pipe maker.

Well into the night,

after a few Pilsner and Schnaps, he began to tell me about a new selection of

briar obtained from an Austrian pipe maker named Peter Matzhold. It was

explained that this Austrian had the best briar he had ever seen and was

fortunate to purchase a number of briar block from him.

A relatively unknown

Austrian pipe maker with fantastic block was too tempting a treat to pass

up.

Eighteen month later

I had an Email address, a few month after that, I had the pleasure of meeting

the man himself. Quiet, thoughtful and passionate are the words that I find to

describe Peter Matzhold. The lines of his pipes are elegant, almost to the point

of seductive. A Matzhold pipe smokes incredibly dry and cool.

Please continue

reading below and learn more about the man with the unbelievable

briar.

“For a

person who knows nothing about you, can you please share some biographical

information about yourself? Where are you from, where and when were you born,

how did you get introduced to pipes and pipe making, and under what

circumstances did you start making pipes?”

I was born in Graz, Austria in 1952.

At the appropriate time, I began architectural studies. In school my primary

interest had been painting. I also had the urge to creative things for which I

had a daily need, using my own ideas. For example, I made my own furniture and

clothes. It only makes sense that would want to make my own pipes

too.

“Under what

circumstances did you decide to make pipes a occupation?”

After

five years of architectural studies, I worked on a residential building project.

During this time, I was still painting, taking pictures and making pipes for my

own use. After the project was completed, we made a presentation at an

architectural conference in Switzerland. While there, I was smoking my pipes

without really thinking about them. A businessman in Basel noticed these unique

pieces that were not for sale, and he displayed them. Following this showing, a

pipe dealer told me that I should make some pipes just like these for him to

sell. After my experiences with stress of working as an architect, making pipes

in the quiet of my own shop in order to make a living seemed very attractive,

and I began my profession as a pipe maker.

“Has any

person or persons been responsible for modelling your career or your designs?”

“If so who?”

I really wasn’t influenced by other pipe makers. I also didn’t know

anything about factory pipes. I wasn’t interested in “standard” pipes. My pipes

were sculptures and objects, which one could smoke. Sales for these “objects”

were good. But then I met the woman who was later to become my wife and we

wanted to have children. It was clear that I had to sell more pipes. So I began

to make classical pipe shapes. But I always held fast to the idea that these

pipes were not to be copies but were to be developed in their own unmistakable

style. I would describe it this way, if a smoker sees one of my pipes without

knowing who made it and thinks that this must be a Matzhold pipe, and then I

know that it as made right. “What type of briar do you use?

What type of material do you use for mouthpieces? Do you use other materials do

you use to adorn your pipes?”

I only use plateau wood that I

bought from my supplier more then ten years ago. For the stem I use only the

highest quality vulcanite. For certain applications I use other woods that I

think are attractive, like olive wood and kings wood. I also like horn with its

wonderful natural variety of colours, as opposed to the artificial colours and

forms of acrylic, which I would never use.

“What is the

most important aspect of a block of briar for you?”

Every

year my supplier gathers several hundred blocks from which I can make my

selection. These are, of course, more expensive. I look for the density of the

grain, as well as, the consistency of the plateau and the likelihood of finished

pieces. I don’t pay attention to how the grain runs because I have had the

experience that it is easier to make a classic shape from a consistent grain,

but a wild, irregular course of a naturally beautiful grain challenges me more,

and gives me over and over again the chance, compelled by the grain to create

new shapes and variations. An important aspect is also how I run my shop. I

started more than ten years ago to buy more wood, as was made possible by my

financial situation. I have already told my supplier last year that I wanted to

buy around eight hundred pieces. I am working with wood that has been cured a

minimum of five years in the space under my roof. When I’m not sure, at the

moment, what to make with some of the pieces of wood in my stock, I put them

aside and try later. It goes without saying, that it is very comforting to know

that I have a stock of wood that will last several years, should I not be able

to buy new wood of a quality that I would wish to have.

“What is the

most important aspect of the mouthpieces?”

The mouthpieces must be as

comfortable as possible when held in the mouth. The pipe cleaner must pass

easily through the stem to the bottom of the bowl, whether the pipe is straight

or bent. The mouthpiece is not simply the connection from the bowl to the mouth,

but is a component of the design. The bowl and stem mutually result in the style

and character of the pipe. Both can be seen in a continuing line of unity from

the bowl to the end of the stem or as individual components of the pipe. Each

individual bowl must have its own mouthpiece and thereby gets its

character.

“Where do

you get your inspiration for your shapes?”

Naturally in the course of a year I

have a large variety of shapes in mind, but the block itself determines the

shape of the pipe. My procedure is not to plan to make a particular shape and

then look for a particular block to make it. I take a piece of wood and decide

what should be made from it. This not only creates much less stress for me, but

new ideas and variations always come when I deal with the uniqueness of each

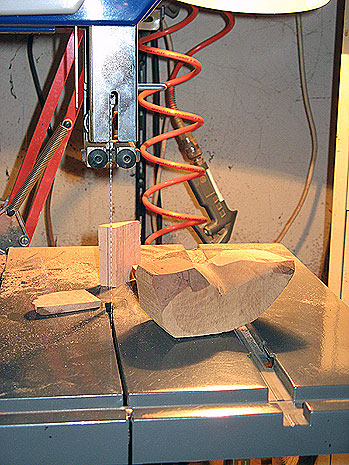

block. It is essential that the bowl not be turned on the lathe and also not the

smoke hole. I do all drilling by hand after I am certain of the shape of the

pipe.

“How has

your work evolved over the years?”

“Is there one particular aspect of your

work that gives you the most satisfaction?”

Over the course of the years after

searching through the variety of shapes I have made, there is one fundamental

concern I have. That is my hope that they should be recognized by consumers. I

didn’t just dream this up, this is my personal conviction. And it seems that I

have had the good fortune that my development of shapes speaks to many pipe

smokers. If that weren’t so I couldn’t enjoy with satisfaction my profession. I

wouldn’t be me and would have to, for example, make pipes in a Danish or Italian

style. I admire these styles and have the deepest respect for those who make

them. They are one fact of an extensive supply. I am another individual in the

world of pipes, and it would be greatly satisfying for me if I were recognized

as an unmistakable individual in the pipe world.

“In your

opinion, what distinguishes and identifies your work from the work of other pipe

makers?”

There are a number of pipe makers who all have the same goal – to do

their best. They are concerned with what is perfection and in exactness of

workmanship, and how their future work will reflect their understanding of shape

and style. Every pipe maker who doesn’t try to copy others but brings his own

individual uniqueness to his work enriches the pipe world.

“How many

more years do you plan on making pipes?”

I will be fifty next year and know

many people who are already thinking about retirement. They must retire at some

time from their professional life. Fortunately, no one can force me to take

retirement. As I see it today, I love my work and only two things could stop it

– sickness or incapacity to work – or that pipe smokers would not want my

pipes.

After smoking a

couple of Matzhold pipes, I find it impossible to think that pipe smokers would

force Peter into retirement. Peter Matzhold, a lovely man that makes a fabulous

pipe. The simple elegance of a graining stain and carnauba wax make a Matzhold

pipe immediately recognizable.

The Matzhold grading

system is easy to follow, A to G, and then his top grade CU that stands for

Casper and Una, Peter’s two

children.

Copyright © 2008 by TECON GmbH

with friendly support of Peter Matzhold & Philip Thomson |