History of Hilson - Since 1846

Staff Hillen 1950

The Natural home of Hilson ...

The Dutch have the reputation of being astute and inventive, with a strong feeling for tradition and yet, at the same time, a modern approach to life. They are critical towards others but also set high standards for themselves. Whilst aspiring to quality and perfection without concessions, the Dutch are known as individualists: men and women with a will of their own, who pursue their own tastes with quiet assurance.

A small province of the southern Netherlands and northern Belgium is home to the Limburgers, connoisseurs who not only appreciate the good things in life but also know how to create them. In a region where flamboyance and a philosophical outlook on life go hand-in-hand, the pipe smoker recognises instinctively that Roermond, situated at its centre, is the natural home of Hilson.

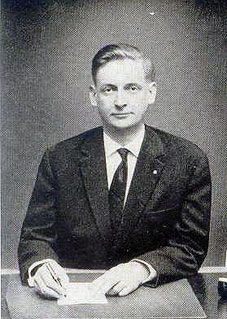

Monsieur Albert Hillen

|

History of Hilson

In 1846 a German named Jean Knödgen started the production of clay pipes in Belgium. At the end of the 19th century Jean Hillen (married into the Knödgen family) took over the company and developed the idea of also producing briar wooden tobacco pipes in his factory. He had some suppliers from the French Jura district turn some bowls which he then finished himself. Some time later he took up the complete production process of briar wooden tobacco pipes so he did not have to depend on others.

Jean Hillen had 2 sons: Jos Hillen who was responsible for sales and Albert Hillen who was responsible for the production of pipes. Albert was also an interpreter in the English army during WWII and he succeeded in establishing many international contacts. Thus they were soon able to export the first pipes manufactured in Belgium to countries all over the world with the brand name HILSON (Hillen and sons).

In 1980 the Hillen Pipe factory from the Belgium-Limburg town of Bree was purchased by the Royal Dutch Pipe Factory where the production of Hilson pipes was continued, carefully observing the traditional craftsmanship.

|

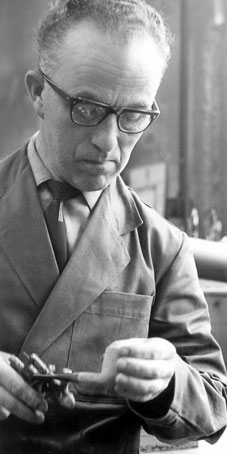

The manufacturing of pipes, a noble craft …

at the Royal Dutch Pipe factory we prefer to speak of a workshop rather than a factory. And rightly so, because in spite of the sweeping technological developments which have occurred in other fields, the manufacturing of tobacco pipes remains a highly-skilled craft. A coincidence perhaps, but a pipe maker resembles the pipe smoker in many ways. He possesses a considerable degree of individualism, patience and an eye for detail. Like the sculptor or diamond-cutter, the pipe maker in his mind has a vision of the final form and texture of the pipe throughout each stage of the crafting process.

|

A pipe maker uses his finely tuned sense of equilibrium and proportion to find the pipe's ideal balance, which has a decisive influence on whether the pipe will feel comfortable in the mouth.

Making a pipe requires a very special affinity for the medium, and experience in working with the unruly and capricious material from which superior tobacco pipes are made: the root of the Erica Arborea, or briar wood. This briar wood, noble and beautifully grained, forces its way through the rocky soil of the area around the Mediterranean and adds 50 years of growth to the value of the pipe Faults and imperfections are revealed as the wood is crafted. The pipe maker can never predict with certainty that the block of wood will actually be transformed into the pipe he visualises or the high quality pipe with which the Royal Dutch Pipe Factory has built its reputation. It might even end up as a piece of firewood, for not without reason do the old pipe makers say "Top quality is found, not crafted"

And indeed, tobacco pipes are crafted, not manufactured. They are crafted by experts, who have learnt their noble skills through many years of practice.

A speciality of Hilson is the addition of a meerschaum insert into the first-quality briar root tobacco pipes. Meerschaum is a fossil which is extracted in Turkey. The material is very light, porous and it absorbs fluid. It also adds a sweet taste to the tobacco and because of the double sides a cooler smoke is realised.

|

|

|

The synthesis of tradition and technology….

While preserving the distinguished tradition of crafting pipes, the Royal Dutch Pipe factory has succeeded in developing a modern factory with a sophisticated and efficient process.

Contemporary technology creates the ideal dry climate to bring out the best in the 50 year-old blocks (ébauchons). The ébauchons are sorted electronically and the finishing, polishing and sandblasting processes are carried out with modern machinery. In a laboratory equipped with advanced measuring and testing instruments, new stains and varnishes are developed and tested with due respect to environmental considerations.

Pipe smokers are individualists. The Royal Dutch Pipe Factory does justice to their individualism with a collection of pipes that allows pipe smokers to express themselves … because a Hilson also reflects a lifestyle.

|

Copyright © 2007 by TECON GmbH

with friendly support of Royal Dutch Pipefactory - Elbert Gubbels & Zonen BV |