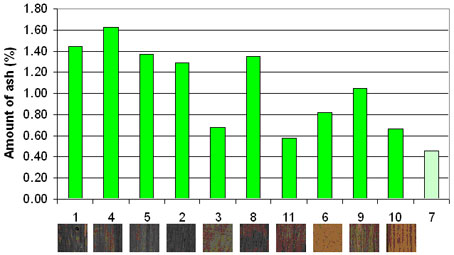

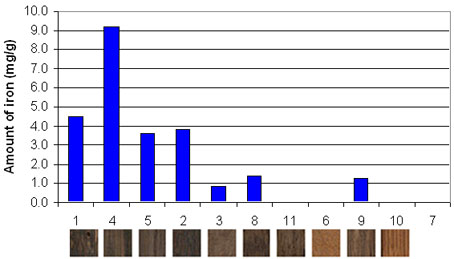

Figure 1: scanned surface of the 10 bog oak samples

Not all described tests were done at all

samples. Mainly, the samples with a good ability to produce pipe bowls were

tested. Especially at the determination of the age, restrictions of the quantity

of samples were necessary.

Methods and results

During stuffing and smoking a lot of changes within the wood of the

pipe-bowl are taking place. These changes have a strong influence on the ability

to use the wood for pipes and furthermore on the quality of smoking. Different

tests which describe the changes in the wood during the stuffing and the smoking

were chosen. The tests started with the identification of the age of the wood

and the wood density. The equilibrium moisture content, the water uptake and the

swelling are describing the chemical condition of the wood and the affinity to

water. The increased affinity to water is due to a changed amount of the degree

of crystallisation of the cellulose. During the degradation, the amount of

amorphous parts of cellulose could be increased, which makes it easier for

water-molecules to access the wood. Characteristics like swelling and shrinkage

are important for the stability of the bowl during stuffing and smoking. The

chemical analyses present the inorganic composition of the wood; i.e. the amount

of ions which were introduced during the buried period.

Determination of age with the

help of Carbon-14

The determination of age (sample number 1 to 4)

was done at the University of Vienna, Vienna Environmental Research Accelerator

(VERA), Prof. Wild (see tab. 1). The age varied between 1300 and 5000 years.

Table 1: Carbon-14 dating of the four samples (BC = before

Christ; AD = ano domini)

There is no strong relationship between

the scanned surfaces (Fig. 1) and the age (Tab. 1). The colour seems to be

dependent on parameters like the condition during burying.

The smoke ability

The smoke ability, which means the ability to use the raw material,

was classified by Mr. Prammer following the school grades; 1 = excellent; 5 =

insufficient (see Tab. 2).

Table 2: Smoke ability of the different samples

Ranking the samples according to their

intensity of colour, it’s obvious, that light-coloured samples are related to

bad smoking conditions (see Tab. 3).

Table 3: Smoke ability, ranked with school grades

The used reference – Bruyère – is

described as species with good characteristics

Wood density

Die

The wood density is one of the universal wood quality parameters. The wood

density is strongly related to various characteristics. For the sub fossil oak

it is also a measure of the degree of degradation. .

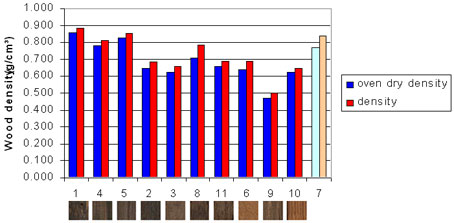

Wood density was determined as oven dry

density (wood density of completely dry wood) and as wood density at an

equilibrium moisture content at the standard climate (20°C, 65% relative

humidity resulting in approximately 12% moisture content).

The results of the oven dry density show

a strong variation between 0,62 und 0,86 g/cm³. Wagenführ and Scheiber (1985)

presented density values between 0,58 and 0,73 g/cm³. The reference (Bruyère)

had a density of 0,77 g/cm³ (see Fig. 2).

Figure 2: Oven dry density (blue) and wood density (at 12 %

moisture content; red) of the samples; sorted by the smoke ability. The sample 7

is Bruyère.

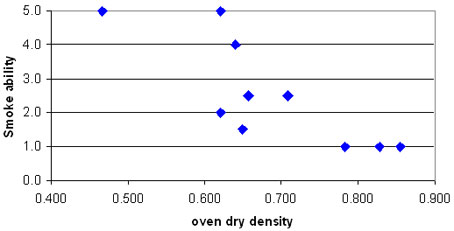

A strong relationship between density

and smoke ability is visible: A high wood density is necessary to produce high

quality pipe bowls (Fig. 3).

Figure 3: The relationship between smoke ability and oven

dry wood density (without sample 7).

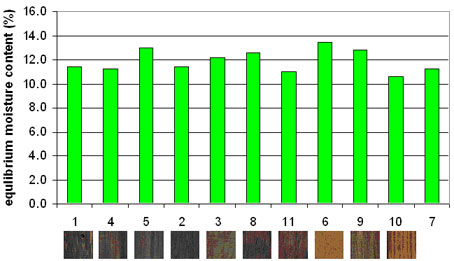

Equilibrium moisture content

Storing wood under a given constant climate, the samples reach

given moisture content. The samples were stored under standard climate (20°C,

65% rel. humidity) for several weeks. Spruce wood reaches under such conditions

12% moisture content. Deviations can occur due to changes in the chemical

composition.

The measured values varied between 10,6 and 13,5% (see Fig. 4).

There is no relationship between this parameter and the usability.

Figure 4: Equilibrium moisture content of the samples

(sorted by the smoke ability); 7 = Bruyère

The swelling

Due to

the hygroscopic behaviour of wood, moisture from the air can heighten the

moisture content of the wood. Below the so called fibre saturation point (about

30% of moisture content; the cell walls are saturated with water, but there is

no liquid water in the holes of the cells) ongoing drying processes cause

shrinkage of the wood. If the wood gets moistened again, it swells in the same

relation like the shrinkage occured.

The three anatomical directions of the

wood differ in swelling and shrinking. In tangential direction it’s twice than

in radial direction. The proportion between longitudinal : radial : tangential

is 1:10:20.

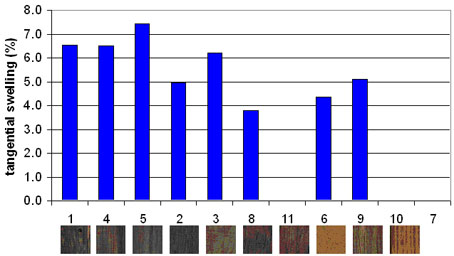

Due to the highest values, the tangential swelling coefficient

was chosen. Wagenführ und Scheiber (1985) reported about values of 6,9 to 14,2%.

Due to sometimes not perfectly orientated samples the volumetric swelling

coefficient was also calculated .

The values of the tangential swelling

varied between 3,8 and 7,4% (see Fig. 5), which is lower than described in

literature. These low values are caused by the general high variability of this

parameter, as well as by the fact that the samples were not perfectly oriented.

Bruyère is not growing in aligned directions like wood. Therefore a comparison

is not possible.

There is a weak tendency of high values

at samples with good smoke ability.

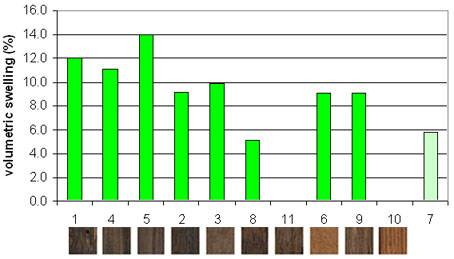

The results of the volumetric shrinkage

(Fig. 6) confirm the trends seen at the tangential swelling coefficient.

Basically you can see that samples with higher swelling coefficients are more

suitable for smoking.

Figure 5: Tangential swelling of the samples (sorted by the

smoke ability)

Reduced swelling coefficients are

usually a hint of a “modification” of the wood, which happens also at the

steaming of wood. Changes in the organic chemical composition (cellulose,

lignin, hemicellulose) reduce the swelling coefficient as well. There is a

strong relationship between density and swelling. That means, if density and

chemical composition is reduced – due to degradation of the wood – also the

swelling becomes lower.

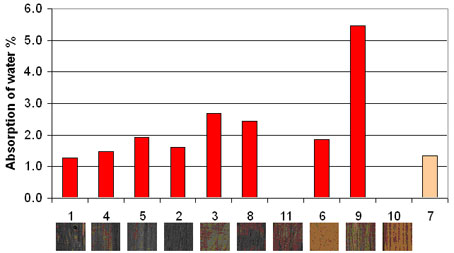

Moisture Absorption

The ability to absorb water is important for the bowl of a pipe.

During the smoking the wood has to absorb water from the tobacco. We tried to

simulate this process. Oven dry samples were stored above liquid water for 20

minutes (there was no contact to the water). The samples were weighted prior and

after the test and the water uptake was calculated.

Figure 6: Volumetric swelling of the samples (sorted by the

smoke ability; 7 = Bruyère)

Figure 7: Absorption of water (sorted by the smoke ability;

7 = Bruyère)

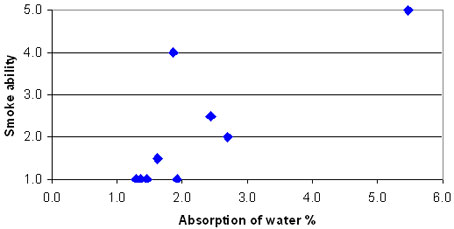

Figure 8 shows, that there is a

relationship between water uptake (within 20 minutes) and suitability of the

wood to build pipe bowls. The best samples take up less water then the worst.

The amount of water absorbed by samples with the best smoking qualities is the

same like for Bruyère.

This parameter seems to be also a hint of the organic

chemical composition of the wood (degree of degradation).

Figure 8: The relationship between the smoke ability and

absorption of water in 20 minutes (without the samples 7, 10, 11).

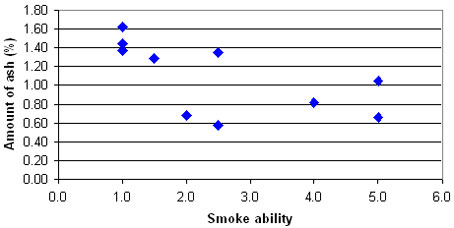

The amount of ash

The determination of the amount of ash:

One to two grams of dry

wood were getting to ash in an oven at 700°C. At the first part of the

oxidation, the pot was closed to ensure, that no ash is going to loos during the

intensive burning of the carbon. After one hour the pot was opened, and stood

inside the oven for three more hours. After cooling the mass loss was determined

(see also Fengel and Wegener 1989). At least two determinations per sample were

done.

Figure 9: Amount of ash (sorted by the smoke ability; 7 =

Bruyère)

When you measure the amount of ash you

can derive the amount of inorganic substances (mainly salts) within the wood.

Wagenführ and Scheiber (1985) mentioned an amount of 0,8% for sub fossil oak.

The determined values were between 0,5 and 1,6% (see Figure 9), which meets the

descriptions of literature.

The amount of ash in fresh oak wood is 0,2%

(Wagenführ and Scheiber, 1985). The higher values of the sub fossil oak are due

to inclusion of salts during the time of burying.

Figure 10: The relationship between the smoke ability and

the amount of ash (without the sample 7).

In the figures 9 and 10 it’s well

visible, that there is a strong relationship between smoke ability and amount of

ash. Samples with good smoke abilities had high amounts of ash. There is a

strong correlation between colour of the wood and suitability to build pipe

bowls. Due to these relationships it seems, that the reaction of iron and the

tanning agents of the wood is responsible for the dark colour of the wood.

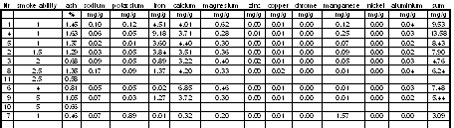

Amount of inorganic elements

Determination of the amount of inorganic elements:

The samples

were dried for 48 hours at 40°C and 80 mbar in a vacuum oven. 500 to 700 mg of

the dried samples were used for the analyses.

A high pressure microwave

digestion was chosen, which was done with the agents: 0,5 ml 30%igem H2O2, 1ml

70%iger HClO4 and 6ml conc. HNO3. A program with different heating and cooling

phases was chosen. After 35 minutes of digestion and cooling, the liquid was

filtered and purified water was added up to 50 ml. The qualitative and

quantitative analyses were done with the help of a flame AAS (Atomic Absorption

Spectroscopy) and ICP-OES (Inductive Coupled Plasma Optical Emission

Spectroscopy).

The following elements were determined:

Sodium, Potassium, Iron, Calcium, Magnesium, Zinc, Copper, Chrome,

Manganese, Nickel and Aluminium.

Table 4: Amount of ash and elements (sorted by the smoke

ability)

Table 4 presents, that just the elements

iron, potassium and magnesium show high values. Fengel and Wegener (1989)

described potassium and magnesium as the most frequent elements in wood. They

play an important role during wood formation.

So, the values of iron are the

most interesting ones for sub fossil oak.

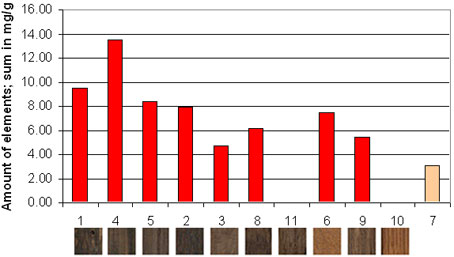

Figure 11: Amount of elements (sum) (sorted by the smoke

ability; 7 = Bruyère)

The sum of elements shows interesting

relationships to the smoke ability (see Fig. 11). A good suitability to produce

bowls is connected with high amounts of elements. The sum of elements correlated

well with the amount of ash. Therefore it can be assumed, that all important

elements have been determined. Just silicates could have been included at some

of the samples.

The sum of elements is lower than the amount of ash. This

fact is probably based on the missing determination of anions. Metals can be

found as oxides in the ash, which is not the case in the natural condition of

the wood.

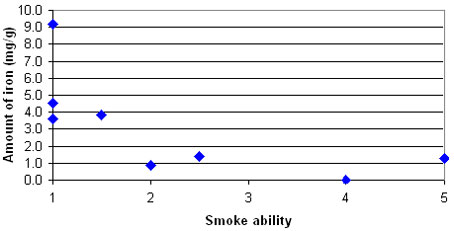

Primarily iron, potassium and magnesium

play a role for the sum of elements (see Table 4). Because of the high impact of

potassium and magnesium on the formation of wood, iron was presented alone

(Figure 12).

The reaction of iron with tanning agents

of the wood is responsible for the dark colouration of the sub fossil oak wood.

This reaction is also described for fresh oak wood (Fengel and Wegener, 1989).

So, the colour (dark brown, dark grey up

to black) is strongly influenced by the amount of iron in the surrounding

environment, where the trunks were buried over hundreds of years. The dark

colour can be modified by degradation (especially microbial) of the wood –

getting brighter again. To split and quantify these processes in the meaning of

colour is not possible due to state of knowledge.

Figures 12 and 13 present the strong

relationship between the amounts of iron and the smoke ability. The darker wood

samples have higher amounts of iron and are better to produce pipe bowls. That’s

also a confirmation of the high importance of the reaction between iron and the

tanning agents on the colour of the wood.

Figure 12: Amount of iron (sorted by the smoke ability; 7 =

Bruyère)

Figure 13: The relationship between the smoke ability and

the amount of iron (without sample7).

Abstract and conclusions

Under wet conditions wood can be preserved thousands of years. Sub

fossil oaks can be found in the gravel of rivers as well as in bogs. Under

anaerobic conditions just a slow microbial degradation of wood takes place

(Rowell und Barbour 1990). If these conditions do not always exist, a

degradation of the wood caused by fungi and mold can occur. These processes can

also take place at standing trees, prior the burial processes.

So, the quality of the sub fossil oak

wood can vary greatly. This project was established to find possibilities to

determine the suitability of different origins of sub fossil oak to produce

bowls of pipes in advance.

The age of these buried oak trunks

varies greatly. The radiocarbon dating presented an age of 1300 to 5000 years.

This enormous difference in age does not influence the suitability and the

colour. It’s not possible to estimate the age with the help of the colour.

The most important parameter, which is

connected to the suitability to produce pipe bowls, is the degree of degradation

and the chemical properties.

Various

parameters confirmed this statement:

-

The colour

presents a strong relationship to the smoke ability. The darker coloured samples

(dark grey up to black) are better applicable. The dark colour is linked to the

reaction of iron and tanning agents, which is mainly described for oak wood.

-

The wood

density has to be high to produce good bowls. The highest value was 880kg/m³,

which is higher than cited in literature (615 – 760 kg/m³). The wood density of

oak wood varies between 430 and 960 kg/m³ (Wagenführ and Scheiber 1985). A high

wood density of the living oak tree and good preservation can be attributed to

the high density of the sub fossil oak.

-

Swelling and water uptake are linked

to the condition of the sub fossil wood. These parameters can be altered

especially by changes of the organic-chemical composition of the wood. Wood with

good qualities to produce bowls has high coefficients of swelling and reduced

potential of water uptake. The highest values of tangential swelling of sub

fossil oak wood are comparable to the values of fresh oak wood.

-

There

is a strong relationship between the amount of ash and the smoke ability. A good

suitability is linked with a high amount of ash.

-

The amount

of elements – especially iron – is high in samples of good suitability. As these

samples are dark coloured, it might be linked with the reaction of iron and

tanning agents.

Concluding, the best qualities to

produce pipe bowls have to be of high density and dark colour.

Zitierte Literatur:

Fengel, D., Wegener, G. 1989: Wood.

Chemistry, Ultrastructure, Reactions. Walter de Gruyter, Berlin.

Rowell, R.M., Barbour, R.J. 1990:

Archaeological Wood. Properties, Chemistry and Preservation. Advances in

Chemistry Series: 225, American Chemical Society, Washington D.C.

Wagenführ, R. Scheiber, C. 1985:

Holzatlas. VEB Fachbuchverlag Leipzig.

Wien im December 2008

© copyrigth 2009 - Prammer Josef –

Ungenach

All rights reserved

Copyright © 2009 by TECON GmbH

with

friendly support of Josef Prammer